BiogasPLUS is the first ready to use additive based on safe and sustainable engineered iron based nanoparticles directed to the optimization of anaerobic digestion processes which increases the production of biogas and concentration of CH4. Thus, the process that converts organic waste into raw matter for energy production is optimized by simply adding a small dose of iron based nanoparticles to either a large waste treatment reactor, a septic tank, or a homemade biodigester, you just spike the nanoparticles solution onto it.

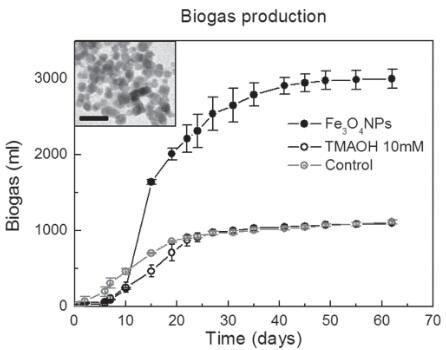

BiogasPLUS is a disruptive technology because it obtains the highest ever-reported improvement of biogas production: triples (200% increase of production) the biogas yield with cellulose as feedstock in laboratory conditions and obtains over a 30% methane ratio increase in real industrial settings, with real feedstock and with optimal concentrations below the 1% (with respect to the Volatile Solids). Such a methane production increase is far above any known technology aimed at increasing biogas production: many existing technologies approach this problem (i.e. pre-treatment of the biomass, thermalization of the waste, combination of feedstock and inoculums) but only obtain modest production increases. Moreover, many tend to be costly to implement since they usually require structural changes in the biogas production process. The unprecedented methane production increase is the most appealing advantage of BiogasPLUS, but it also offers additional differential advantages, including:

1. Increase in both biogas and biomethane production.

2. Improving biomass to biomethane conversion effciency.

3. Better biogas composition (higher methane share).

4. Reduction of the digestate fraction (more biogas means more digestion).

5. Higher waste degradation (the digestate is less, and less reactive).

6. Increase digestion process stability (more reproducible).

7. Acceleration of the digestion process. Reduction in retention/residential time.

8. Proven to reduce H2S levels (precipitated in the form of pyrite).

9. Reduction on the amount of foam produced (small particles trap detergents decreasing foam).

10. Enrichment of the residual material (digestate) with iron ions to obtain by-products with increased economic value such as high quality fertilizers.

11. Solution to inhibitory substances. Rescue of digesters with problems.

12. Simple additive that can be just spiked onto the incoming sewage (it does not require any change in the biogas plant industrial process).

13. It does not require pre-treatment of the substrate/feedstock or maintenance to preserve the microorganisms.

14. Enlargement of biomass feedstock (oil, fat, meat) as it has been proved very suitable for “diffcult to digest” (recalcitrant) feedstock.

15. Enlargement of biomass feedstock (low energy waste) due to the increased biogas/methane production.

16. Can be used with any kind of anaerobic digester, the process is fully scalable.

17. Reduce AD plant energy consumption.

18. Minimize undesirable side effects in biogas plants such as the odours associated to HS and NH3, thus reducing the cost of associated conditioning measures.

19. Precipitation (recovery) of phosphorus (in the form of ferric and ferrous phosphate).

20. Disinfection of pathogens and multi-resistant bacteria.

Write a comment